Vehicle and component development by industry-leading experts

Selecting the proper tire and wheel combination for a vehicle is the cornerstone for success. OE production tires are the result of a development process requiring multiple iterations to reach a solution optimized for performance, wear, rolling resistance, weight, cost and other requirements. Wheel specifications including width, mass and stiffnesses must be matched to optimize the performance of each tire.

We ensure the success of your tire program through:

The kinematic and compliant properties of the front and rear suspensions, in combination with the vehicle mass and inertia properties, provide the starting point for suspension development. Spring, stabilizer bar, bushing and mount selection requires detailed evaluations of each component to ensure proper undamped ride frequencies, roll/pitch rates, front and rear lateral compliance characteristics, front and rear fore/aft compliance characteristics and higher frequency vibration isolation.

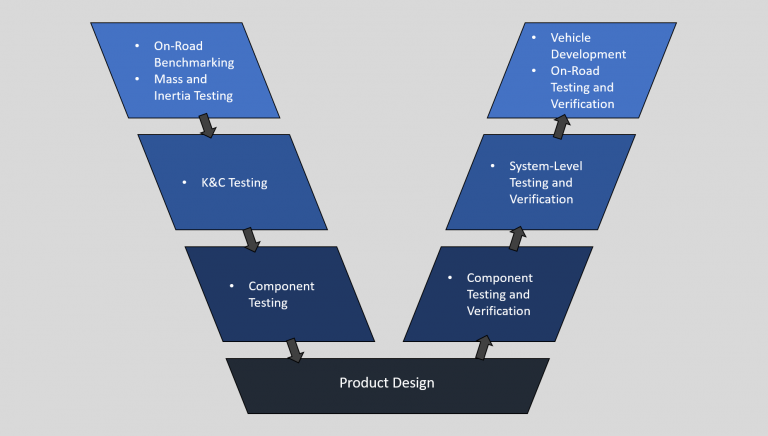

Cayman engineers use our systems engineering approach to develop specifications for each component to optimize system- and vehicle-level performance. This includes the use of the most efficient tools and techniques:

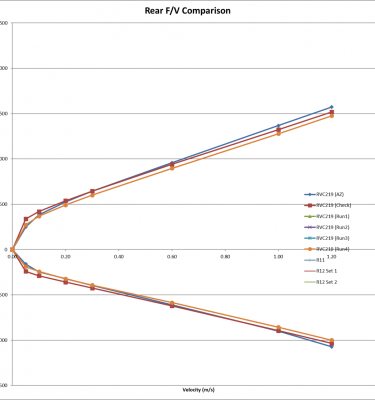

Damper performance characteristics significantly affect every vehicle dynamics and durability attribute. Selection of the proper valving system and optimizing the damper settings to best match each individual vehicle is crucial for success. Cayman engineers have developed a wide range of vehicles with all major damper suppliers utilizing different damper types, sizes and valving systems:

We partner with your damper supplier and conduct subjective and objective on-road testing, shock dynamometer lab testing and perform CAE simulations to develop the optimum settings for your application.

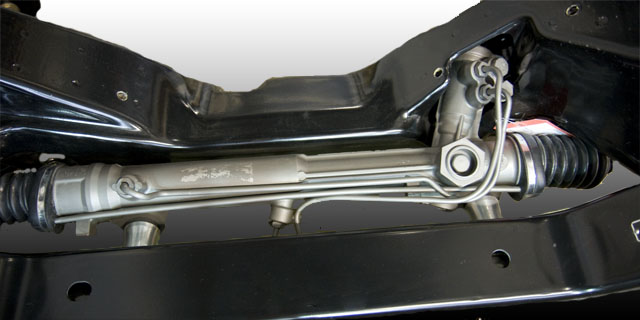

Steering system performance is a key indicator of vehicle capability, quality and character. Cayman engineers have extensive experience developing hydraulic, electric and electro-hydraulic steering gears, pumps, columns and control software with the world’s leading steering system manufacturers. For new vehicle programs, our experts use subjective, objective and CAE tools to select the best system for your vehicle and develop the assist, friction and compliance characteristics for optimized steering system performance. For vehicles currently in production, these same tools are used to improve vehicle vibration or drift/pull warranty claims.

Brake pedal feel is vital to giving the customer confidence in the capability and safety of their vehicle. Stopping distances and fade performance are key metrics utilized by government agencies and media during performance testing. Cayman engineers ensure brake system performance meets or exceeds the vehicle’s desired targets and is consistent with the other vehicle dynamics attributes.

EV and Hybrid-Electric vehicles present a unique challenge in blending advanced powertrain controls, braking controls and the foundation brake system to deliver a confident braking feel while achieving desired range targets. Cayman experts will work with your team to develop the desired braking performance while ensuring the regenerative braking strategy is also integrated with the steering and handling performance targets of the vehicle.

ESC system performance under all vehicle operating conditions is crucial to provide safety for your customers and increasing driving enjoyment when approaching the vehicle’s performance limits. Cayman experts work jointly with your ESC supplier ensuring performance meets NHTSA requirements and your internal standards while being seamlessly integrated with the handling attributes of the vehicle.

But ESC is only part of the chassis control strategy on luxury, high-performance and EV vehicles. The integration of these systems has a dramatic effect on the overall refinement, driver confidence and safety of the vehicle: