Measurement, analysis and interpretation of objective test data using in-house or customer-standard techniques

Objective testing of handling performance on a dedicated vehicle dynamics area (VDA) typically includes constant radius, frequency response, slalom, single- and double-lane change, swept steer and accel/decel maneuvers. Standard or custom test procedures are run based on customer needs and available facilities. Closed course or race circuit testing is performed with similar instrumentation depending on the vehicle type and required data.

Steering Wheel Angle

Steering Wheel Torque

Yaw Rate

Lateral Acceleration

Laser Ride Height Sensors

Vehicle Speed

Vehicle Position

(sample, not all-inclusive)

Roll Gradient

Roll Damping

Linearity

Steering Wheel Torque Gradients

Pitch Gradients

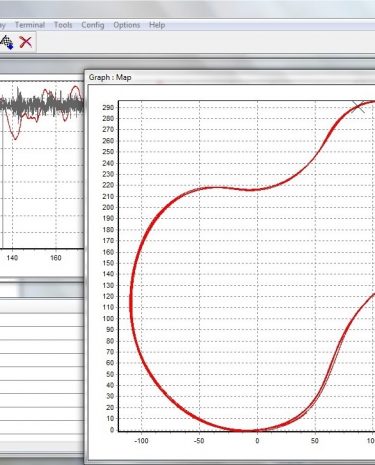

Objective testing of steering performance is typically the most repeatable and used for tire, damper and suspension development or competitive vehicle benchmarking programs. Testing includes low-g sine-steer, swept steer, parking efforts, frequency response and returnability tests. Maneuvers are performed at various predetermined speeds or specific speeds requested by the customer or dictated by the vehicle.

Steering Wheel Angle

Steering Wheel Torque

Yaw Rate

Lateral Acceleration

Laser Ride Height Sensors

Vehicle Speed

Vehicle Position

(sample, not all-inclusive)

Yaw Rate Gain

Lateral Acceleration Gain

Torque/Angle Deadband

On-Center Torque/Angle

Friction/Hysteresis

Objective testing of ride comfort requires very well defined road surfaces and test parameters. Customer and/or vehicle specific test conditions are defined jointly based on available public road or proving ground facilities. Sensor sets typically include multiple accelerometers at different locations around the vehicle resulting in both frequency and time domain measurements. Laboratory testing on a 4-poster rig is used to address specific issues or reduce on-road development time.

Seat Track Vertical Acceleration

Seat Track Lateral Acceleration

Seat Track Longitudinal Acceleration

Steering Column Vertical Acceleration

Estimate of Vehicle Pitch Acceleration

Estimate of Vehicle Roll Acceleration

(sample, not all-inclusive)

Acceleration Spectra (weighted or un-weighted)

Band-limited RMS Values (weighted or un-weighted)

Acceleration Time Histories averaged over repeatable events

Objective testing of braking performance includes both customer-level brake pedal feel metrics as well as stopping distance and fade performance metrics. Data is used for both the brake system and tire development processes.

Longitudinal Accelerometer

Brake Pedal Force

Brake Pedal Travel

Ride Heights

Vehicle Speed

Vehicle Position

(sample, not all-inclusive)

Brake Pedal Force

Brake Pedal Displacement

Deceleration Rate

Vehicle Pitch

Stopping Distance

Reducing customer warranty complaints from error states is crucial to high customer satisfaction ratings. Testing to minimize unwanted vehicle, steering wheel and brake-induced vibration, drift/pull and directional instability is some of the most important objective testing a vehicle manufacturer or aftermarket supplier can perform. Cayman experts perform a suite of objective tests to assess your vehicle’s sensitivity to these error states and either make recommendations or implement changes to improve your customer satisfaction.

Success on the NHTSA defined J-turn, Fishhook and FMVSS126 yaw stability procedure is crucial to every affected vehicle. Cayman will execute these procedures on your vehicle to give your company the highest confidence possible of success.

Cayman works with your engineers to develop custom on-road or laboratory test procedures to diagnose vehicle-specific development problems, aid in component design or replicate customer usage issues. Unique sensor sets, public road driving conditions or proving ground maneuvers are used to diagnose on-road issues. Laboratory testing utilizing a kinematic and compliance machine, 4/7-post shaker or Flat-Trac machine diagnoses problems not easily replicated during on-road testing.